Welcome to the world of wheel repair lathe machines, where the magic of craftsmanship meets the art of restoration. When it comes to giving wheels a new lease on life, these powerful tools play a vital role. Whether it’s a vertical wheel repair lathe or the latest Alloy Wheel Repair Machine, the options are endless.

At wheelcncmachine.com, the official website of Taian Haishu Machinery Co., Ltd., you’ll discover a treasure trove of cutting-edge CNC wheel machinery. As a professional designer, manufacturer, and supplier, they have mastered the art of precision engineering. With their innovative solutions, reviving wheels has never been more seamless.

So, buckle up and join us as we delve into the world of wheel repair lathes. Unleash their magic and witness the transformation they bring to worn-out wheels. It’s time to bring back the splendor and elegance of your beloved wheels, rejuvenating them in ways you never thought possible. Get ready to embark on a journey where craftsmanship and technology collide, as we explore the astounding capabilities of wheel repair lathe machines.

1. Understanding Wheel Repair Lathes

A wheel repair lathe is a highly useful machine that plays a key role in the repair and restoration of wheels. With its advanced technology and precision engineering, this equipment brings out the magic of wheel repair, allowing damaged wheels to regain their original strength and aesthetic appeal.

One popular type of wheel repair lathe is the vertical wheel repair lathe. This machine is designed to vertically hold the wheel in place, allowing for precise and controlled machining. Vertical wheel repair lathes are especially effective in repairing and refinishing alloy wheels, which are widely used on modern vehicles due to their lightweight and stylish design.

One notable manufacturer in the wheel repair lathe industry is Taian Haishu Machinery Co., Ltd., whose official website is wheelcncmachine.com. With their expertise as professional designers, manufacturers, and suppliers of CNC wheel machinery, they have gained a reputation for producing high-quality wheel repair lathes that deliver exceptional results.

By understanding the capabilities and advantages of wheel repair lathes, individuals in the automotive industry can unlock the full potential of these machines. With their ability to restore the condition and appearance of damaged wheels, wheel repair lathes prove to be a valuable asset, satisfying both practical and aesthetic needs.

2. The Role of Vertical Wheel Repair Lathes

Vertical wheel repair lathes play a crucial role in the process of revitalizing damaged wheels. These advanced machines have revolutionized the wheel repair industry by offering efficient and precise solutions. Whether it’s fixing minor scratches or major structural damages, vertical wheel repair lathes have become an indispensable tool for skilled technicians.

One of the key advantages of vertical wheel repair lathes is their ability to restore the original shape and integrity of alloy wheels. These machines use cutting-edge technology to carefully remove any imperfections, such as dents or bends, ensuring that the repaired wheel is as good as new. By utilizing specialized tools and techniques, vertical wheel repair lathes can achieve remarkable results while minimizing material loss.

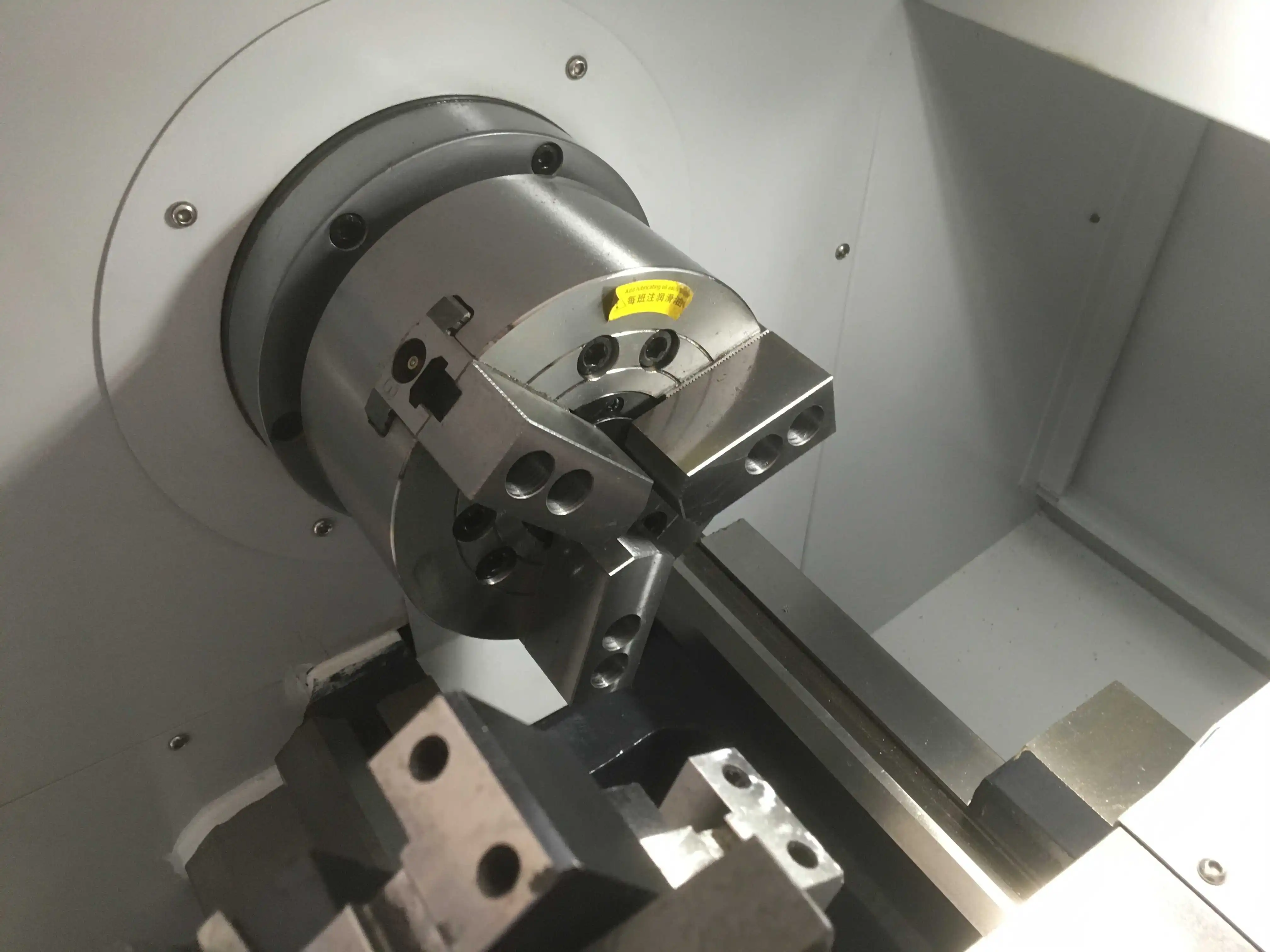

Alloy Wheel Lathe

In addition to repairing damages, vertical wheel repair lathes also give technicians the opportunity to enhance the appearance of wheels. With the ability to precisely cut and reshape the surface, these machines can create customized designs and patterns, turning ordinary wheels into eye-catching masterpieces. The versatility of vertical wheel repair lathes allows for endless creative possibilities, catering to the unique preferences of each customer.

As the official website of Taian Haishu Machinery Co., Ltd., wheelcncmachine.com showcases a wide range of vertical wheel repair lathes, including the highly regarded Alloy Wheel Repair Machine. With their expertise in CNC wheel machinery, Taian Haishu Machinery Co., Ltd. provides top-quality products that are trusted by professionals worldwide. By embracing the power of vertical wheel repair lathes, technicians can breathe new life into damaged wheels, restoring their beauty and functionality with ease.

3. The Advantages of Alloy Wheel Repair Machines

Advantage 1:

Alloy Wheel Repair Machines, such as the wheel repair lathe and the vertical wheel repair lathe, offer a range of benefits for both professionals and individuals seeking to revive their wheels. By utilizing advanced technology and precision engineering, these machines allow for the restoration of damaged alloy wheels to their original form. Wheel repair lathe is a versatile tool that can effectively repair various types of wheel damage, including scratches, scuffs, and dents.

Advantage 2:

One of the key advantages of using alloy wheel repair machines is the cost-effectiveness they offer. Instead of replacing the entire wheel, which can be expensive, these machines allow for targeted repairs. By focusing on the damaged areas, wheel repair lathe and other CNC wheel machinery help save both time and money, making them an attractive option in the automotive industry.

Advantage 3:

Additionally, these machines provide a quick turnaround time for wheel repairs. With their automated and efficient processes, alloy wheel repair machines can complete the restoration task in a fraction of the time compared to traditional repair methods. This speedy process minimizes downtime for both repair shops and individuals, allowing for a more convenient and efficient repair experience.

Overall, alloy wheel repair machines offer significant advantages in terms of cost-effectiveness, precision repairs, and faster turnaround times. With their ability to restore damaged wheels to their former glory, these machines play a crucial role in the revitalization of wheels, providing a magical solution for all wheel repair needs.