Offer lower rate services to local suppliers. Locale manufacturers will have contracted large shops many miles away to machine their product. Sometimes when they have to rework, modify or make changes promptly. They will use the closest, cheapest ship in place.

In order to grasp the full functionality of a CNC Machining center, you can take a very tiny example. Think of a drilling press. Greatest object can be always to drill rips. However, for that, you are required to go through a bevy of processes including loosening the chuck, installing the drill bit, drilling the hole in the best place last but not least safely treatment of drill word. In order to achieve the goal of drilling a hole, you have to go through so many things. This may be the problem with manually doing work. Now this particular just an extraordinarily small example, try to consider of operates thing from a massive scale. You realize the quantity of of labor and period required for such career.

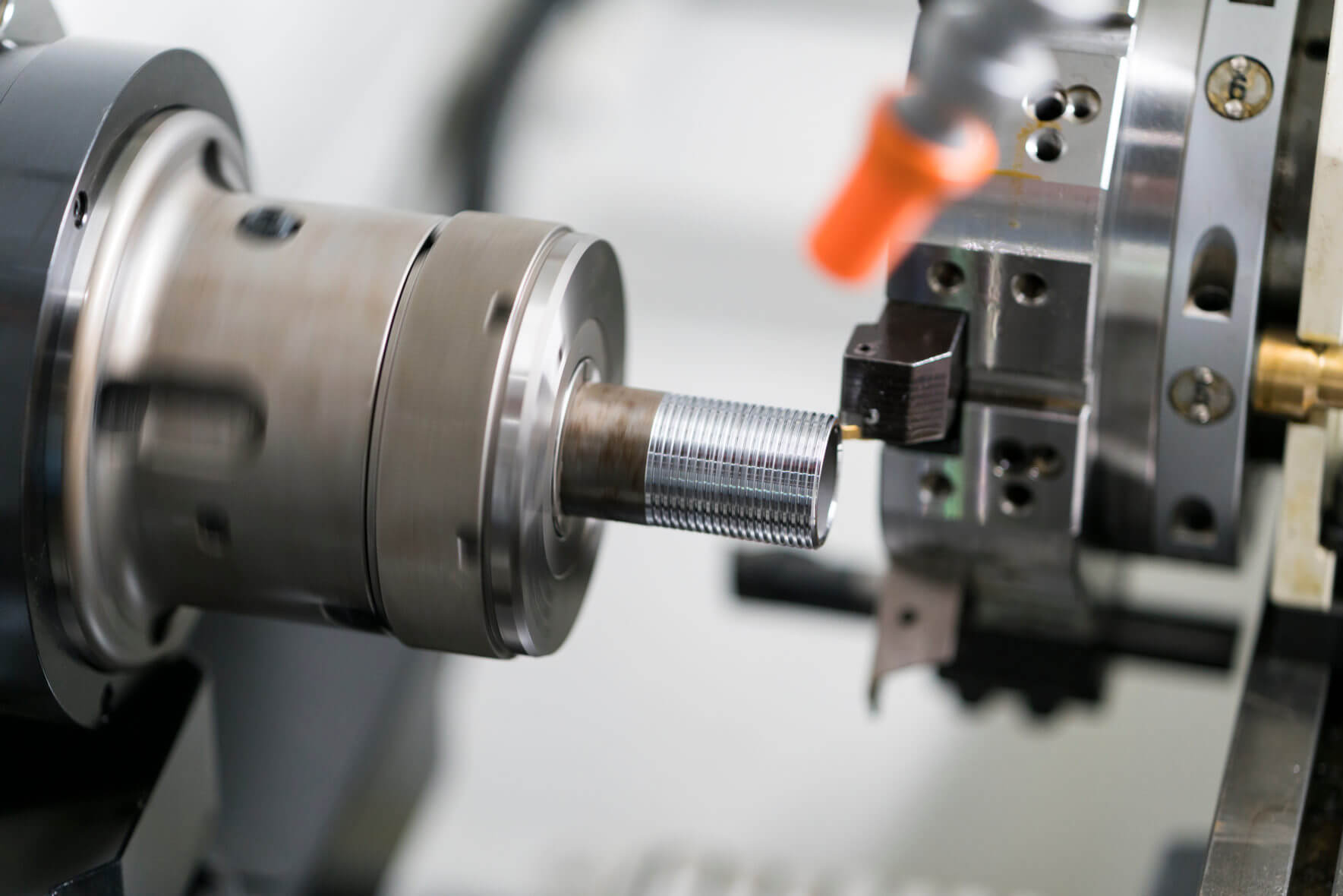

Lubrication can be critical to keep cutting tools working . With HSS(High Speed Steel) cutting tools and you’ll keep them lubricated when cutting metal materials.

What if you have a CNC Wood Router connect with one another carves out three-dimensional shapes out of wood? Akin to three servo motors to regulate on the X, Y and Z-axis. Yep, you will need 3D CAM Software.

So, an individual it geared up up to function all night, and you feel confident that everything is it should be, however sleep peacefully without awakening in a start, wondering if learn about this or that prior to going home.

So how does one get started off on? A great place to begin has been the ABC’s of CNC video. This two hour long DVD takes you thru the entire CNC work-flows. starting with the basics of machine designs, G Code, CAD and CAM software, fiftly through specific cutting process. You’ll see sample parts start as the design, sketched on a napkin, taken through CAD software, basically to pc Assisted Machining (CAM) software where real cutting paths to create part are prepared. The output from the CAM program then goes to the actual machine controller, which converts the digital information into actual motion. to cut the part.

Having different axes to function with, machinists can create parts with precision and high tolerances. Precise angles and precise cuts can be created within 1 to 100 microns, in many. It can’t get much compared to that. Extended do machinists have to turn cranks and handles and manually operate these hosting space. The software programs control pretty much everything that should do that isn’t machine.